Description

This beautiful early 3.8 E-Type OTS came to us after many years of covering very little mileage. We began by following our standard and recommended procedure, carrying out a full inspection of the car’s bodywork and mechanical components from top to bottom. Although the body had undergone restoration many years prior, it remained remarkably rust-free, with fair panel gaps and an overall good finish. However, the mechanical elements required both refurbishment and upgrades to ensure reliable modern-day performance.

The most pressing issue centred on the differential, which, from the factory, should have been equipped with the then-advanced Thornton Powr-Lok limited-slip unit. On arrival, the axle was functioning as an open differential, prompting a full strip-down and detailed inspection. Once the rear cradle and differential were removed, signs of poor assembly and general wear and tear became apparent. The differential was completely disassembled in our transmission workshop and rebuilt with all new friction plates, gaskets, and seals.

While the rear cradle and all brake and axle components were removed for access to the differential, we took the opportunity to carry out a thorough cleaning and degreasing. These components were sympathetically refreshed before being reinstalled with all-new bushes.

Attention then turned to the engine bay and ancillaries. The radiator was upgraded to a discreet yet efficient satin black aluminium high-flow unit. During installation, all new period-correct, cloth-wrapped coolant hoses were fitted. An upgraded cooling fan and temperature sensor were also installed to enhance everyday usability. The exhaust manifolds, which had become visibly rusted, were removed and heat-coated for both aesthetic improvement and better heat management.

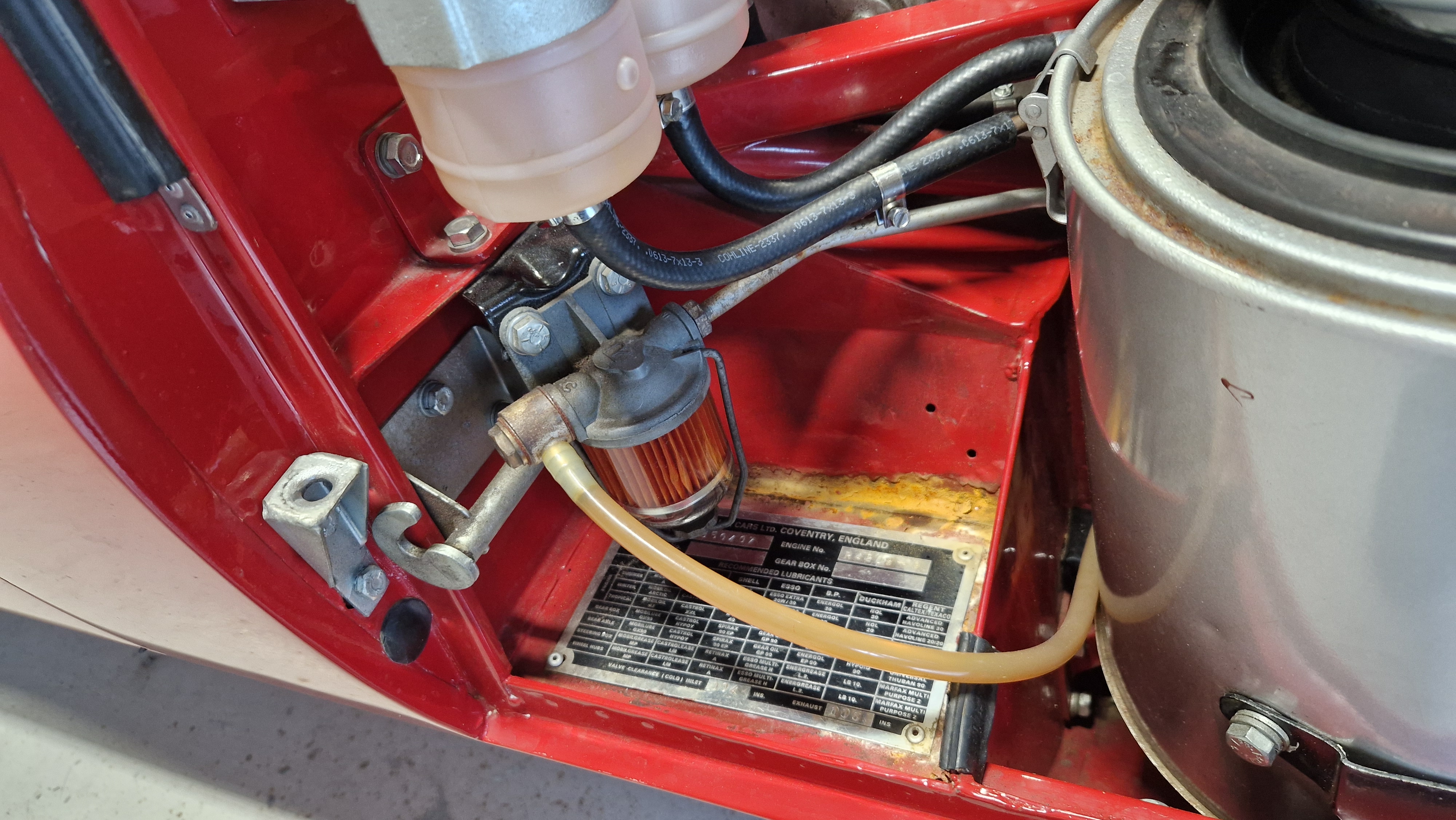

Following a careful road test, it became clear that although the braking system retained its traditional configuration, it lacked the correct feel and stopping power. The E-Type’s brake servo unit requires precise setup; however, in this case, it necessitated a full strip-down and rebuild to restore proper operation.

After carrying out some small and localised paint repairs, the car was ready for final refinements.

To complete the project, we addressed a number of poorly fitting and perished components. This included the installation of a new windscreen and seal, new door seals, soft top seals, headlight ‘bishop’s hat’ seals, bumper edge rubbers, and a new rear boot seal.